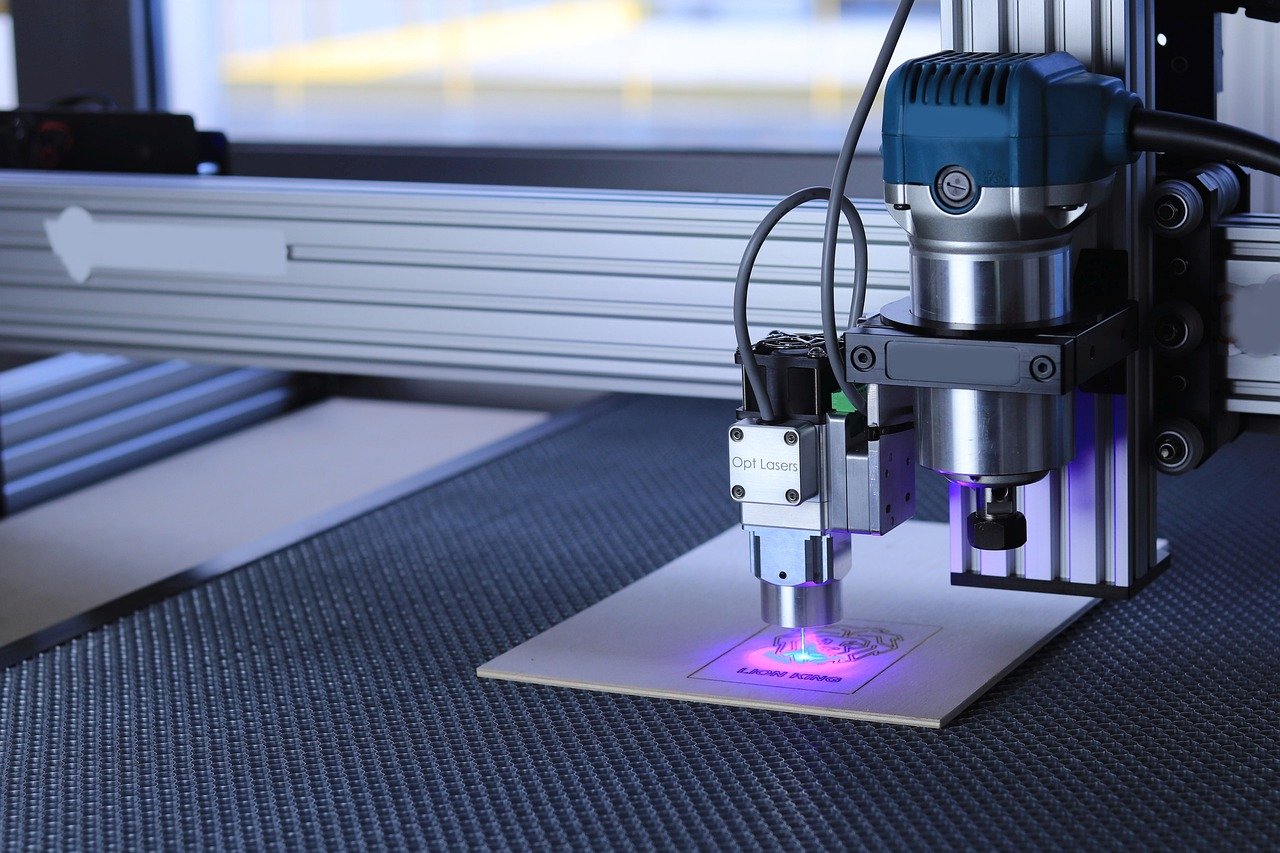

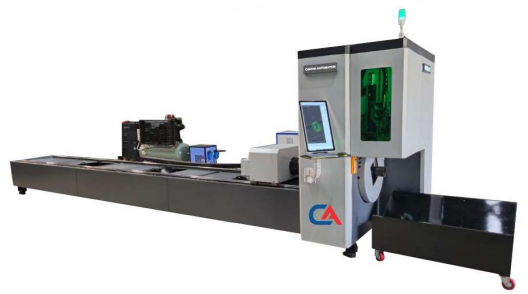

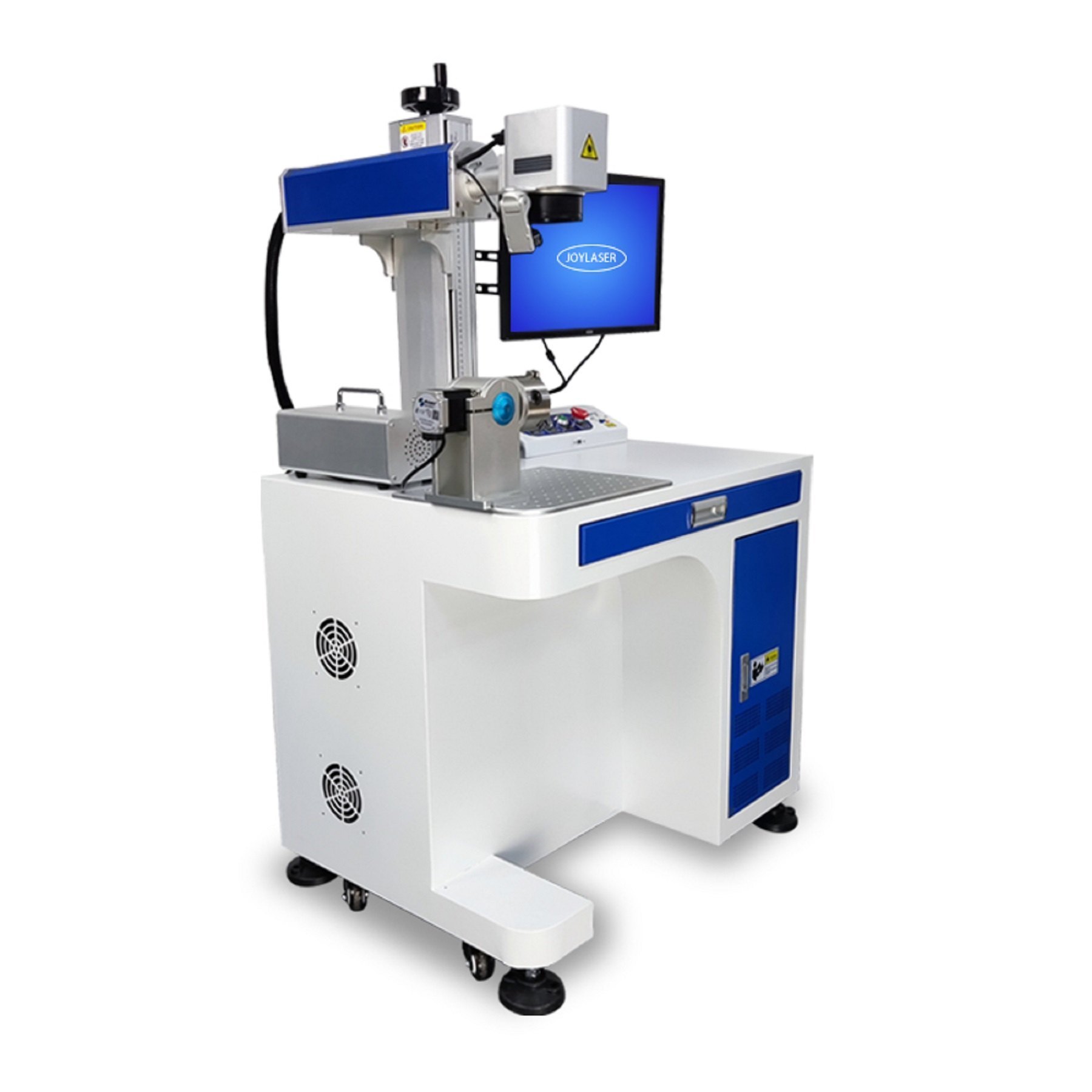

Laser Machine: A laser machine uses advanced technology for cutting, engraving, and marking various materials. It provides high precision, speed, and versatility in industries like manufacturing, medical, and signage. With minimal waste, energy efficiency, and low maintenance, laser machines enhance productivity and quality, making them essential for modern production needs.